Skip Centering! Instantly Verify Machining Without Removing the Workpiece

- Customer

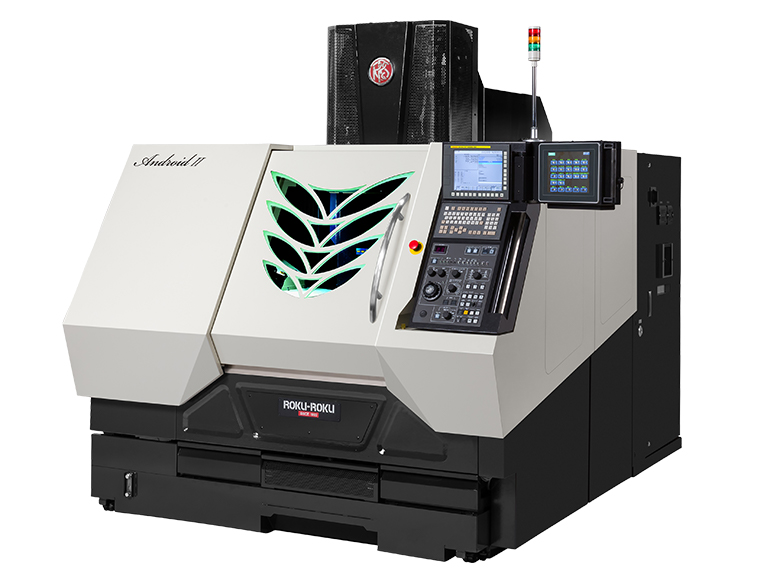

- ROKU-ROKU SMART TECHNOLOGY CO.,LTD.

Customer Introduction

ROKU-ROKU SMART TECHNOLOGY CO.,LTD.

Roku-Roku Smart Technology Co., Ltd. (Minato-ku, Tokyo), with over 120 years of history, is a distinguished machine tool manufacturer specializing in the production of high-precision machining equipment, printed circuit board processing machines, and the development of various specialized machinery.

- Business Activities

- Development, manufacturing and sales of high precision machining centers, micro machining centers, special machining centers, printed circuit board machining centers, and various other dedicated machining centers.

- Location

- Minato, Tokyo, Japan

- Established

- June 16, 1903

- Website

- https://www.roku-roku.co.jp/rokuroku/english/