Enhanced Productivity with Less Eye Strain and Faster Reporting!

- Budget

- Up to 400,000 yen

- Customer

- Electronic Component Manufacturer

Boost Productivity in Visual Inspections Electronic Components!

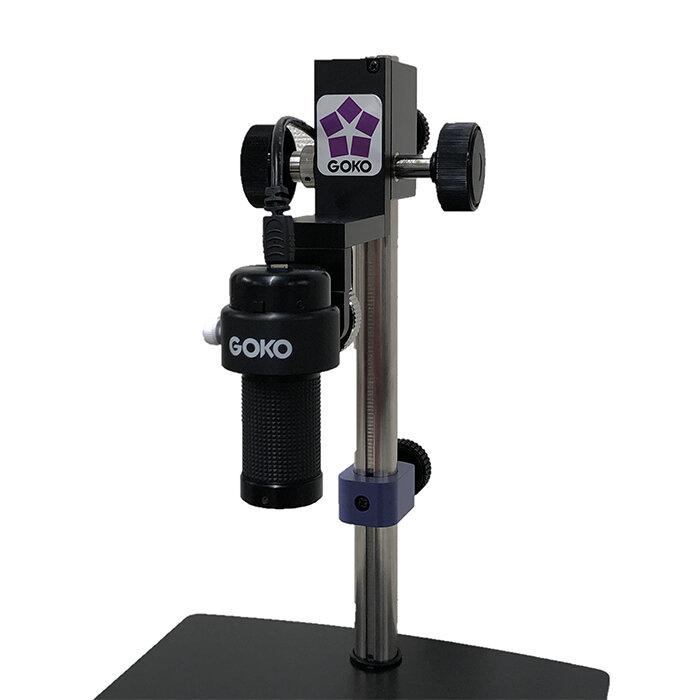

With the introduction of the Multi-Distance Scope GOKO EV-6HD, our customers have significantly enhanced observation accuracy and greatly reduced both inspection and defect report creation times for visually inspecting defective parts during the manufacturing process.

Reducing Eye Strain for Observers, Enabling Stress-Free Visual Inspections

Before introducing the GOKO microscope, our customers often faced significant eye strain due to the lack of clarity and choppy images from their previous microscopes. However, the GOKO EV-6HD now provides bright, crystal-clear images with seamless, smooth screen motion, enabling precise visual inspections without the stress.

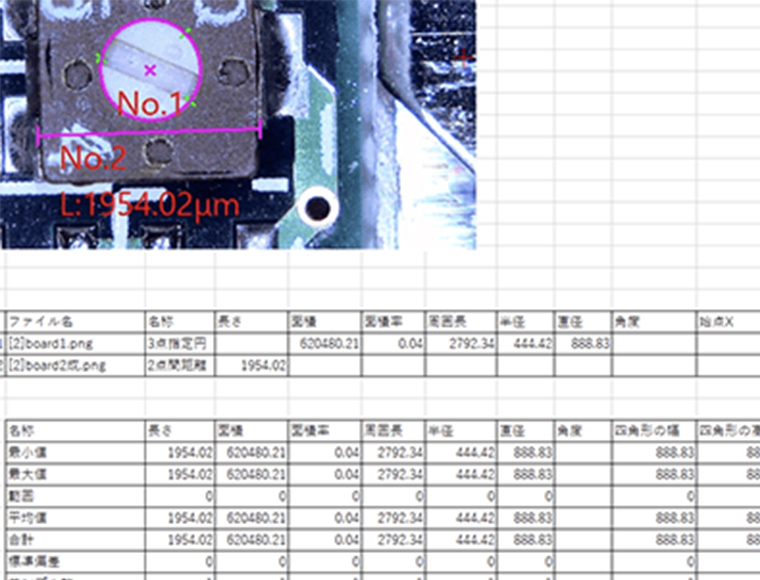

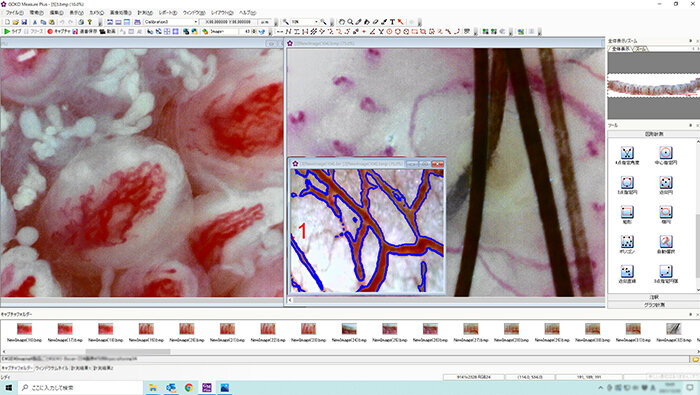

Efficient Inspections, Fast Reporting

Additionally, with the advanced imaging software GOKO Measure Plus, one-click Excel output of images and measurement results enables efficient and accurate inspections along with rapid report generation. As a result, overall productivity has significantly improved.

Got a question or need a quote?

We're here to help.