Success in Monitoring and Improving Cutting Precision!

- Budget

- Up to 200,000 yen

- Customer

- Cutting Parts Manufacturer

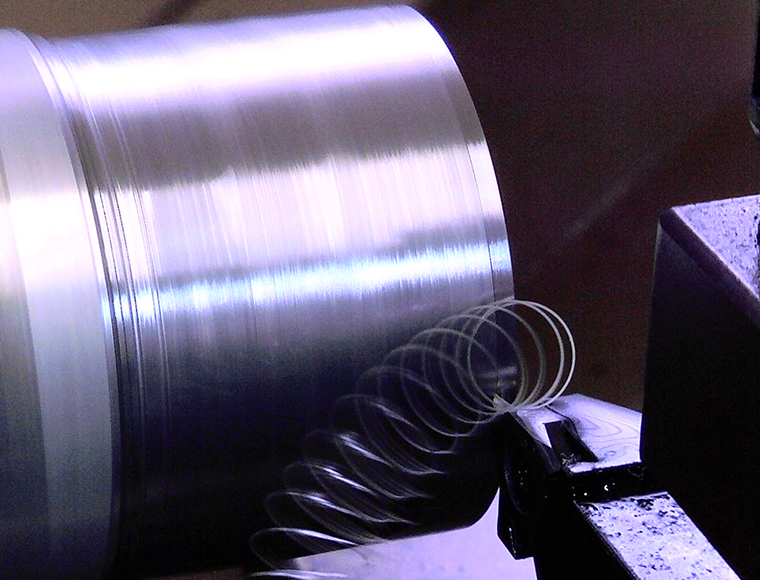

Dramatic Improvement in Blade Wear Observation!

By introducing the Multi-Distance Scope GOKO EV-6HD, the accuracy of observing blade wear on lathe cutting machines has seen a dramatic improvement.

Quick & Accurate Blade Replacement Timing

Previously, blade replacement was determined solely based on total processing time. Now, with the GOKO EV-6HD, the customer can assess blade wear with greater accuracy and speed. This leads to enhanced precision and a significant boost in cost-effectiveness.

Crystal Clear, Seamless Observation

The bright, clear images and seamless, smooth motion provided by the Multi-Distance Scope GOKO EV-6HD allow for stress-free, precise observation of cutting edges, significantly contributing to these improvements.

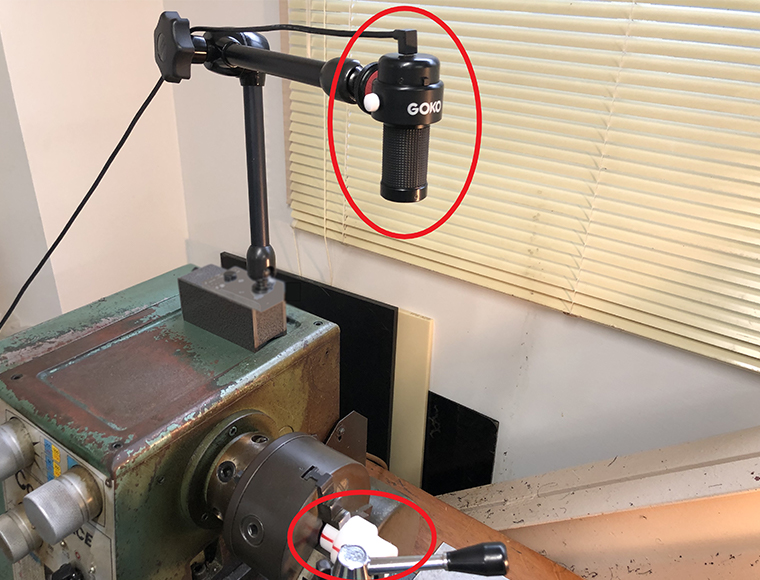

Achieve Flexible Camera Positioning

The Multi-Distance Scope GOKO EV-6HD comes standard with a dedicated holder compatible with a tripod screw, allowing

easy attachment of the optional flexible arm. You can freely adjust the camera's position and

angle.

We offer two types of flexible arm: the standard type "1" and the robust type "2".

Additionally, you can choose between a magnetic type and a clamp type, depending on the mounting location. Feel free to contact us for more information.

Got a question or need a quote?

We're here to help.