Success in On-site Blade Check and Rapid Quality Control!

- Budget

- Up to 300,000 yen

- Customer

- Tool Sharpening Service Provider

Instant On-Site Tool Wear & Sharpening Check

With the introduction of the Handheld Ultra Microscope GOKO EV-13, quick on-site assessment of tool wear and post-sharpening condition is now possible.

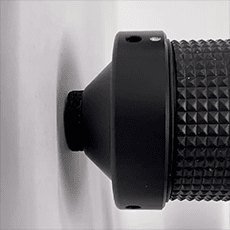

Unique Non-Slip Mechanism for Easy One-Handed Inspection

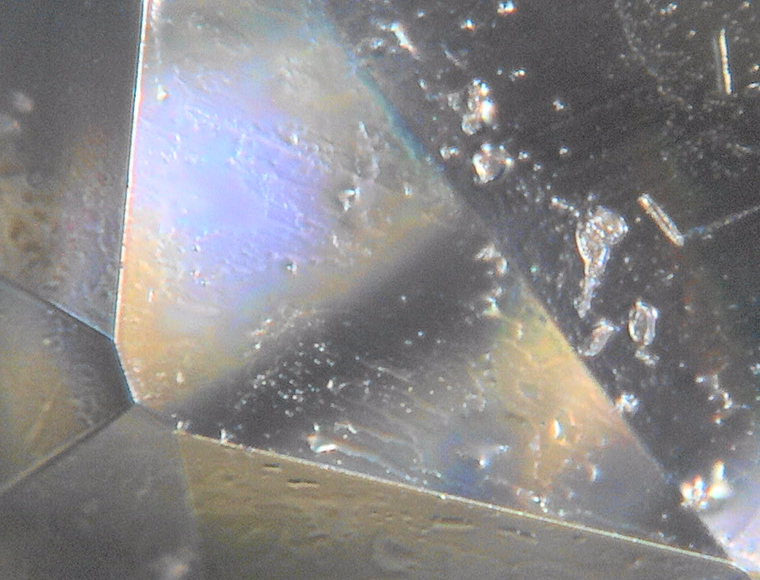

The GOKO EV-13 is highly praised for its deep depth of field and crystal-clear images. Its unique non-slip mechanism ensures excellent handling, even during handheld blade inspections. With no need to bring blades under a stationary microscope, ultra-magnified observations can be performed instantly on-site, significantly speeding up the workflow.

"Perfect for detailed inspections of blade edge chipping and product quality!"

Customers praise it for excelling in magnified inspections of blade edge chipping and cut product quality, as well as being ideal for observing the tips of fine components like needles.

Got a question or need a quote?

We're here to help.