Skip Centering! Instantly Verify Machining Without Removing the Workpiece

- Industry

- Customer

Boost Productivity, minimize Costs! Discover how GOKO’s microscopes have unlocked new possibilities.

Check Machining Status Without Removing the Workpiece ― No More Centering!

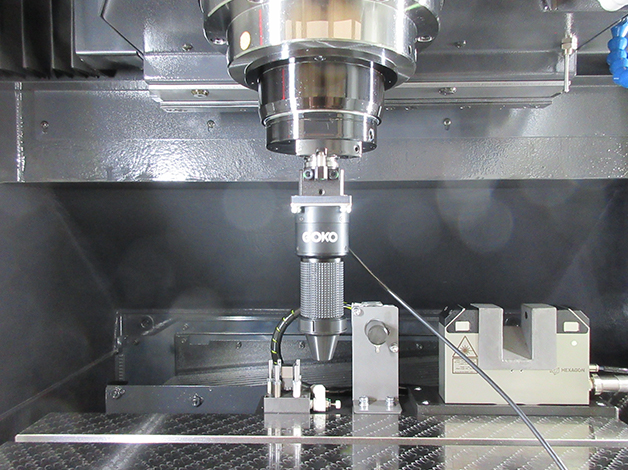

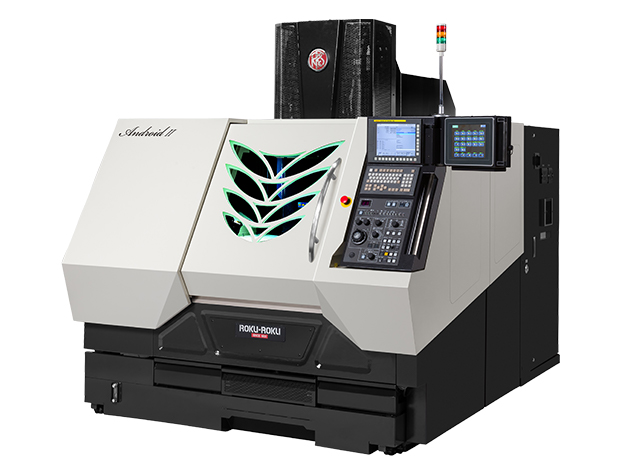

Roku-Roku Smart Technology Co., Ltd. has adopted a customized model of the GOKO EV-6HD Multi-Distance Scope as an optional inspection camera for their machining centers. With this solution, they can now verify the machining status without removing the workpiece from the machine. This eliminates the repetitive task of centering, significantly improving operational efficiency.

Compact Design, High Magnification: Precision for Enhanced Productivity

"We find the GOKO EV-6HD Multi-Distance Scope incredibly convenient because it's compact enough to be mounted on the spindle head and allows us to observe the entire workpiece table," shared Roku-Roku Smart Technology. "Despite its small size, the high magnification is a perfect match for our machine tools."

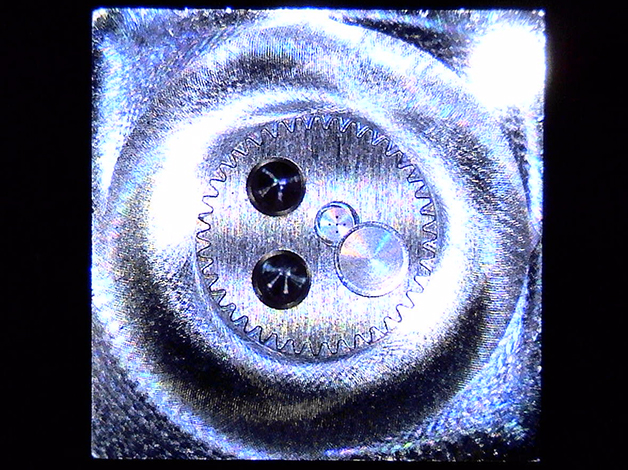

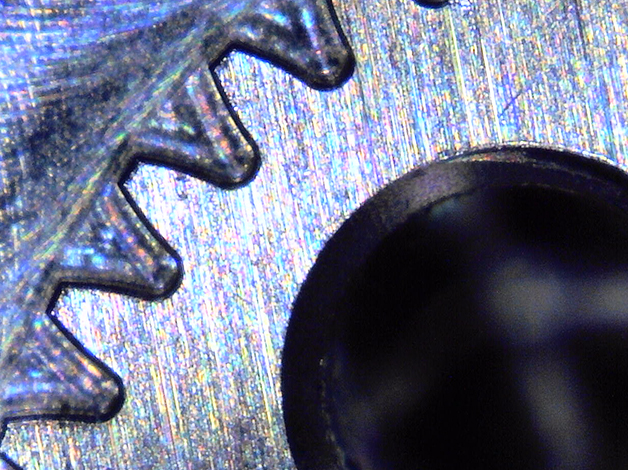

• Outer: Micro Gear with Minimum R0.1mm

• Center: Micro Holes, φ0.1mm, 5 Holes

• Center Left: Micro Tapped Holes, M2, 2 Holes

From Infinity to Macro ― One Scope for Clear, Seamless Observation

The GOKO EV-6HD Multi-Distance Scope offers bright, clear images and seamless video across a broad range of focus, from infinity to close-up. Its compact design, with a total length of only 90mm, makes it easy to install even in confined spaces, such as inside machinery.

For this implementation, we customized the scope to fit perfectly with the client's machine tools, achieving optimal installation. GOKO provides flexible customization options and is happy to accommodate orders starting from a single unit. Please feel free to contact us for more information.

Devices in Use

Explore Related Success Stories

- Instant Metal Precision Check for Automotive Parts on the Line

- Improved Productivity in Scale Alignment

- Real-time Observation of Cutting Parts

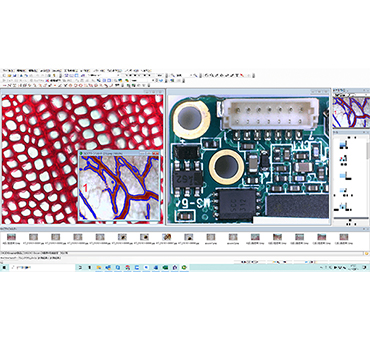

- Visual Inspection of Electronic Components

- Quick Check of Blade Wear and Grinding