Boost Efficiency with Instant Precision Checks for Automotive Parts on the Line

- Industry

- Budget

- Customer

Boost Productivity, minimize Costs! Discover how GOKO’s microscopes have unlocked new possibilities.

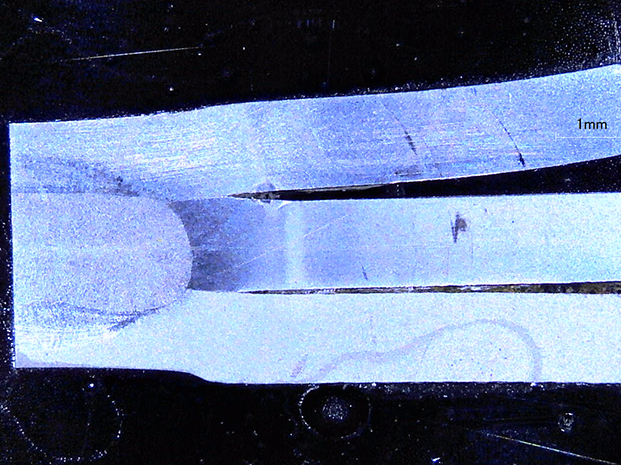

Verify Precision On-Line Quickly and Accurately for Maximum Efficiency

With the introduction of the GOKO EV-6HD Multi-Distance Scope, Bellsonica Co., Ltd. is now able to verify and inspect the metal machining precision of automotive parts directly on the production line. This has eliminated the need for internal movement to the inspection area, significantly improving work efficiency.

"Portable and High-Precision? Unbelievable!"

"We never expected to achieve high-precision observation and measurement with a portable microscope. While other high-precision microscopes are stationary, requiring the subject to be brought to the scope, the GOKO EV-6HD is lightweight and portable, allowing us to carry it anywhere. High-precision observation and measurement can be conducted right on-site. Additionally, its calibration function ensures reliable results," said a satisfied user.

"We also found it to be cost-effective. Despite its low price, it offers high magnification for both observation and measurement, making it an attractive option. The low cost facilitated a smooth adoption process," they added.

High Precision, Easy Setup! GOKO's Microscope for Any Application

The GOKO EV-6HD Multi-Distance Scope, while compact at just 90mm in length, delivers seamless and smooth images, from infinity to close range. Using the standard tripod screw-compatible holder, you can easily attach an optional Flexible Arm to freely adjust the camera's position and angle.

Additionally, the Flexible Arm comes in two models: the versatile Type 1 and the robust Type 2. Depending on the installation site, we also offer magnetic and clamp-type mounts. Customization is available from a single unit, so feel free to contact us for your specific needs.

Devices in Use

Explore Related Success Stories

- Improved Productivity in Scale Alignment

- Check Machining Status Without Removing the Workpiece

- Real-time Observation of Cutting Parts

- Visual Inspection of Electronic Components

- Quick Check of Blade Wear and Grinding